SCADA stands for Supervisory Control and Data Acquisition. SCADA systems are computer-based systems that monitor and control industrial processes. They can be used to monitor anything from power grids, oil pipelines, and wind turbines to factory production lines, water treatment plants, and traffic systems. SCADA system interview questions and answers are a great way to see how a candidate would fare in a high-pressure industrial environment.

Below you can find our list of questions and answers for SCADA topic. Anyway if you have more just make a comment below so we can extend this post for new engineers together.

What is SCADA?

SCADA is an industrial control system used by the operator to control and monitor the processes. It can be used in a variety of industries, from electrical utilities to manufacturing.

You can read more details here.

What is Data Acquisition?

Data acquisition refers to the method used to access and control the information or data of the equipment that is controlled and monitored. The data that is accessed is sent to a telemetry system ready to be transferred to the different sites. They can be analog and digital information collected by sensors, such as flowmeter, ammeter, etc.

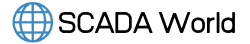

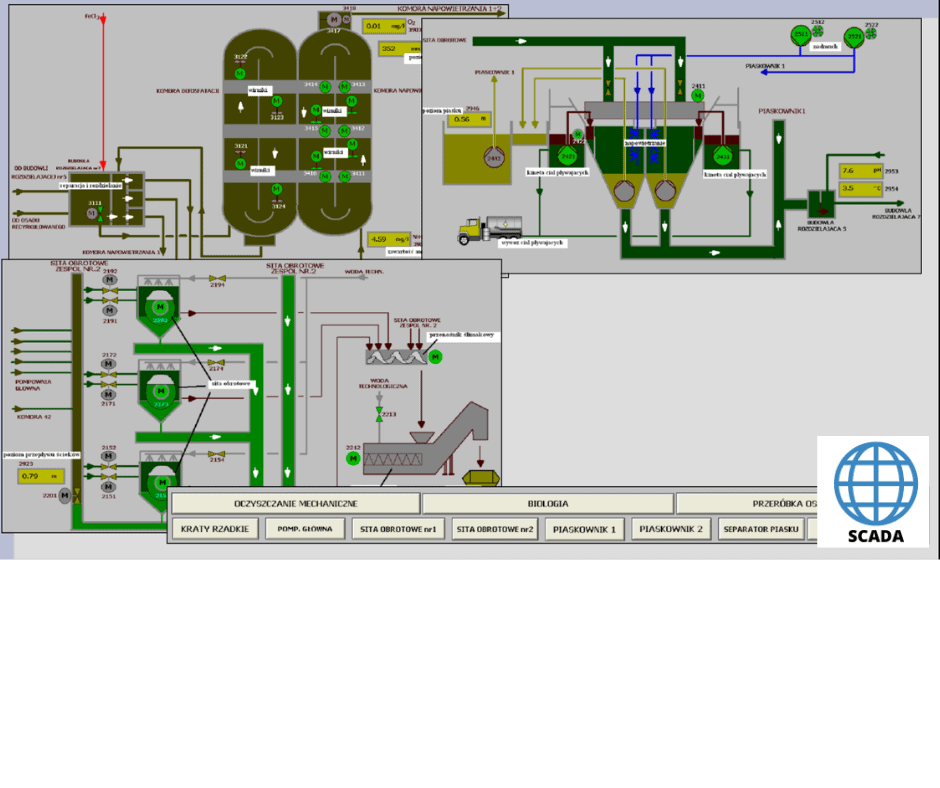

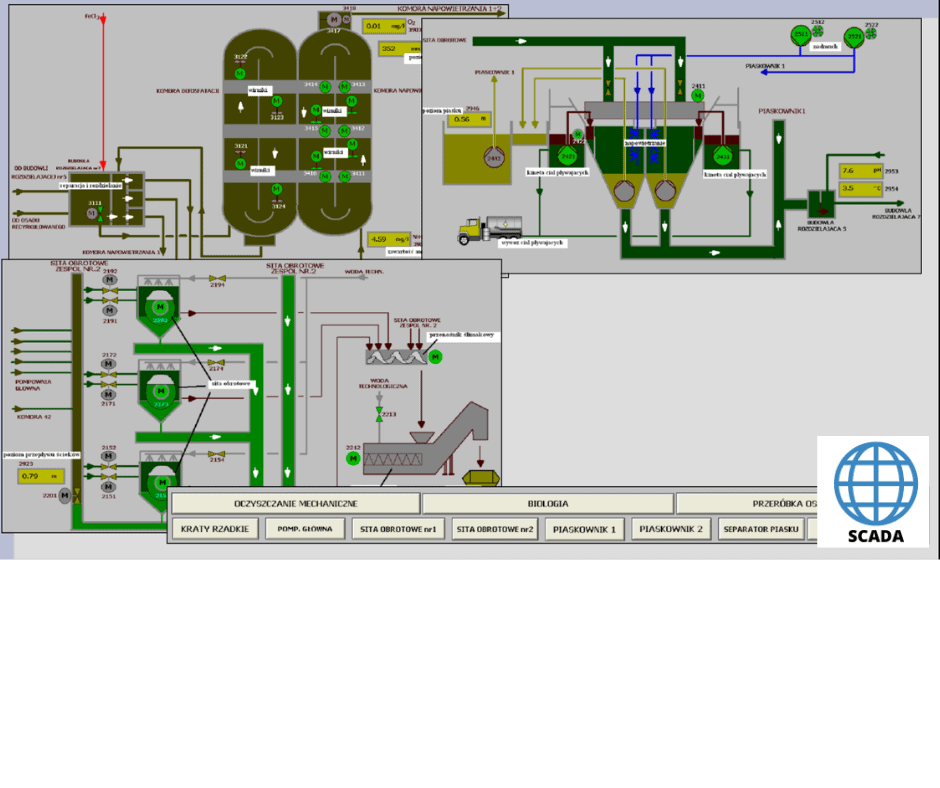

Where we can find SCADA applications?

- Power distribution

- Water treatment plant

- Water treatment station

- Energy consumption system

- Industrial automation

- HVAC

- Airport

What is SCADA historian?

Historian is a service that collects data from different devices and stores them in the database. It stores data in the time series database and can retrieve it to study the performance of a system.

Global SCADA manufacturers?

- Siemens WinCC

- Aveva (Wonderware) InTouch

- Rockwell Automation FactoryTalk

- Ignition

- Display and operate with system views (operator or operators can decide on activities throughout the entire production line from one place)

- Display status and animations of motors, valves, sensors

- Communicate and operating with PLC and all things connected to it e.g. motors, valves, sensors

- Data logging of process values (e.g. temperature, pressures, positions)

- Display trends ( printing, exporting)

- Alarm logging (alarm, failure, error, event)

- Display alarms (printing, exporting)

- Control processes in local or remote localizations (some SCADA can work worldwide)

- Allow operator to see malfunction in real-time

- Reporting and printing specific data

- Connection and operate with databases

- Possible to integrate with MES and ERP

- Long term history (Historian)

- Integration with high-level languages (C#, .NET, JAVA, VBS)

Is SCADA a HMI?

Generally speaking each SCADA is a HMI but not every HMI can be a SCADA system.

If you have any more idea for SCADA System Interview Questions and Answers let us know so we can help fresher SCADA engineers get into industrial automation.